CONCEPT

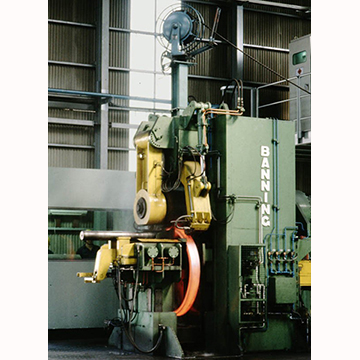

“Forging of Machine Parts for General Industrial Machinery, as well as Components for Space, Superconductivity, Aerospace, Maritime, and Nuclear Applications”

Our commitment to forging technology dates back to 1921. Starting with the creation of tools for processing “stone,” our forging techniques have evolved to meet the advanced demands of industrial machine parts over the years. We have continuously pursued unique technological innovations without being satisfied with the status quo.

Going forward, to respond to increasingly sophisticated customer needs with high added value and the highest quality, we are dedicated to the development of all personnel involved in technological innovation and the enhancement of advanced and optimal equipment. Through systematization, we aim to examine and develop the most rational manufacturing technologies from various perspectives, striving for the formation, development, and inheritance of our unique and rich technological framework.

Company Overview

| Company Name | Nakamura Ironworks Co., Ltd. |

| Location | 147-1, Kakuzo, Noguchi, Komaki, Aichi Prefecture Japan. |

| Capital | ¥25,784 in thousands |

| Representative Board Director | Kengo Nakamura |

| Scope of Business | Forging, heat treatment, machining of metals and business related there of. |

| Monthly Production Capacity | 1500tons of free forgings |

| Affiliated Companies | NTK Holdings Co.Ltd. ・ NTK Co.Ltd. |

沿革

- 1921

-

Founded at Imaike, Chikusa-ku, Nagoya

- 1936

-

Constructed a forging shop at Yada-cho, Higashi-ku, Nagoya

- 1951

Organized as a corporate person

- 1967

Purchased a land site of 43,000㎡ at Noguchi, Komaki City, and started of construction of a machining and cutting shop (Shop No.2 of today)as phase one of the new plant construction plan.

- 1968

-

Started transfer of production department to this site, as the first construction phase came to an end. Started construction of a machining shop and recreational facilities as phase two of the new plant construction plan.

- 1969

Started export sales to the United States and South-east Asian Countries.

- 1974

-

Received the Aichi Prefectural Governor’s award for remarkable plant rationalization.

- 1978

Constructed a forging shop (Shop No.1 of today) as phase three of the new plant construction. Received the Special Commendation for Industrial Tree Planting Campaign Drive sponsored by Aichi prefecture.

- 1981

-

Enlarged forging capacity by constructing a new forging shop (Shop No.3 of today) for phase four of the new plant construction plan. Introduced a 1600tons forging press.

- 1983

-

Approved by Nippon Kaiji Kentei Kyokai(NKKK).Opened a branch office in San Francisco, U.S.

- 1986

-

Started production of forgings for vitally important parts of the V2500 turbo-fan engine.

- 1988

-

Constructed Shop No.3 as part of phase five of the plan. Introduced a 800 tons oil hydraulic crank press.

- 1991

-

Introduced a 250 tons ring rolling mill.

- 1994

-

ntroduced a 1000tons oil hydraulic forging press.

- 1997

-

Introduced a 500 tons high speed forging press.

- 2000

-

Enlarged capacity by constructing Shop No.4 as part of phase six of the new plant construction plan. Introduced a 4000 ton oil hydraulic forging press. Registered ISO9002 certification.

- 2003

-

Constructed shop of grinding.

- 2006

-

Introduced a 8000 ton oil hydraulic forging pess.

- 2009

-

Introduced an 1800 ton oil Hydraulic forging press.

- 2013

-

Registered JIS Q9100 certification. Introduced a Ring-Rolling mill(1050ton/3000mm)

- 2016

-

Purchased land of 19,800 m2 adjoining the north side of existing site.

- 2018

-

Transferred the cutting shop and inspection area to the purchased adjoining land. Constructed a dormitory in the adjoining land of the factory.

- 2020

-

Constructed Shop No.6 . Introduced a S4(4000tons)oil Hydraulic forging press.

- 2025

-

Installed a 1250tons high speed forging press.

Is there anything I can assist you with?

For inquiries about our products, technology, quotations, after-sales service, or other matters, please feel free to reach out through our contact form.

We look forward to hearing from you.